Waste Reduction

We are working to reduce CO2 emissions and to resolve issues such as the recycling and use of waste materials by reducing waste in our business activities.

We are building partnerships and collaborating with various stakeholders to resolve the environmental issues required of the fashion industry.

Inventory reduction/Waste reduction through purchasing management

During the production process of products, use a large amount of water, energy, and other resources.

In the apparel sector, too, there are issues such as unsold items due to overproduction in anticipation of mass consumption, the generation of inventory, and CO2 emissions due to the incineration of waste.

In order to minimize our impact on climate change, we are taking measures to avoid overproducing products and reducing unsold inventory, considering the impact on the environment.

We will reduce wasteful production through the following activities and measures. We also aim to minimize the final disposal of slow-moving inventory by promoting sales in each channel.

1. Optimization of purchasing

Anticipating demand, we are reforming our MD to improve delivery accuracy and QR accuracy.

2. Improve production planning accuracy

We are able to respond to flexible production plans, such as pre-order orders and made-to-order production through crowdfunding.

3. Improved digestibility

Improve product digestibility through quick response and flexible additional production.

4. Reduction of samples

Use 3D cad to reduce the number of samples to be made.

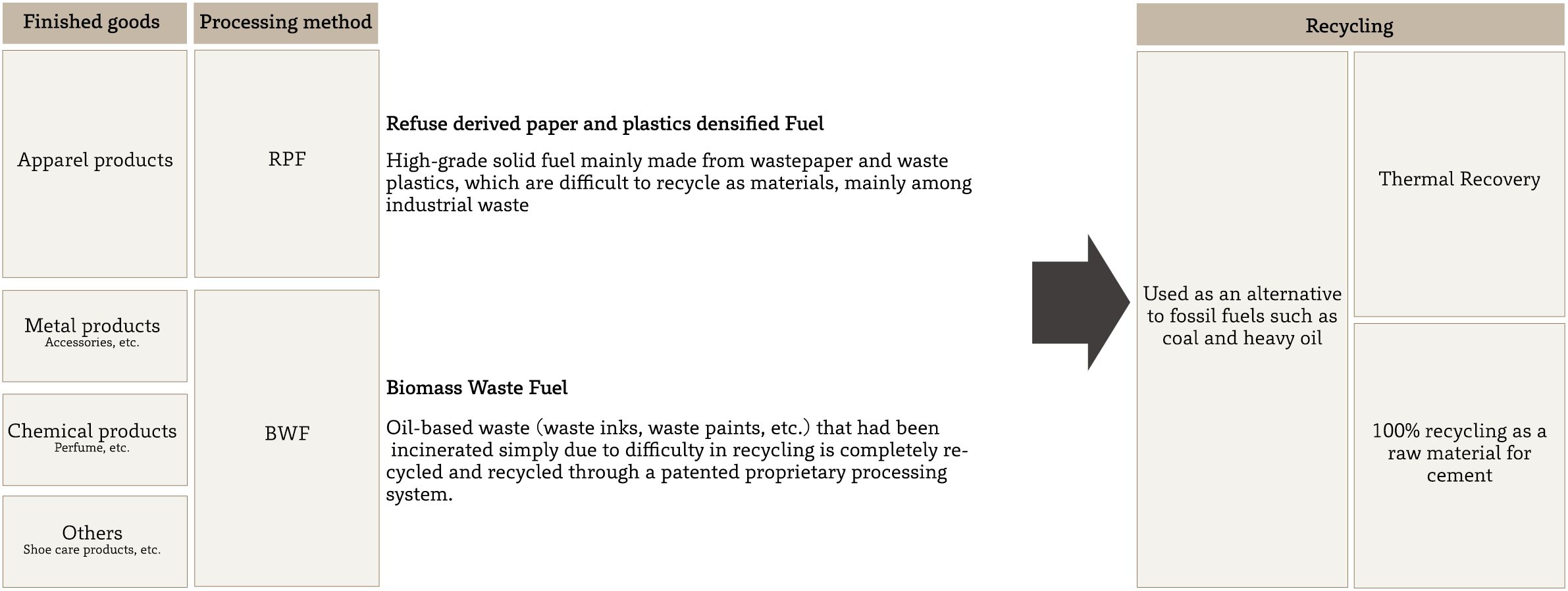

Recycling of products

We recycle all unsold products that cannot be sold.Specifically, we partially offset the environmental impact by converting products into solid fuels for recycling as energy. Metal products that cannot be converted to RPF are recycled into BWF , which is then recycled as a raw material for cement.Through these treatment methods, the landfill/incineration of our products is eliminated.

Recycling of textile offcuts

We have started an initiative with our main supplier, the textile trading company TAKISADA-NAGOYA Co., Ltd. to recycle textile offcuts generated at our own factories, Sanyo Sewing Co., Ltd.

In this project, we will recycle textile offcuts from wool materials.

The textile offcuts are transformed into recycled RE:NEWOOL®, where all processes from reclaiming wool to spinning, are conducted in Japan through TAKISADA-NAGOYA Co., Ltd.. We will then procure RE:NEWOOL® as a raw material.

Through this initiative, we will promote recycling from fiber to fiber and contribute to reducing the environmental impact by reducing waste at our own factories.

Minimization and recycling of office building waste

We are pursuing the following initiatives with the aim of minimizing and recycling waste generated in office buildings.

Paperless operations

- Workflow of internal applications

- Electronic in-house paper media, etc.

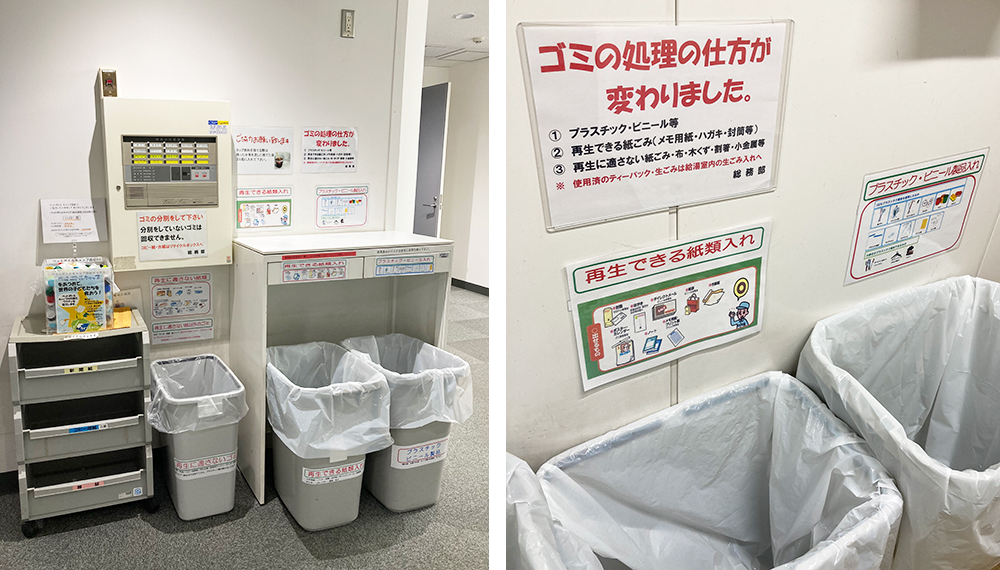

Thorough separation

- Installation of trash boxes that are easy to separate

- In-house awareness of separation rules

Internal enlightenment activities

We conduct in-house training to waste reduction.

In-house training held in August 2025

Contents of the training

- Reasons for waste reduction

- Waste reduction at the planning and production stages

- Waste reduction at our own factories, etc.