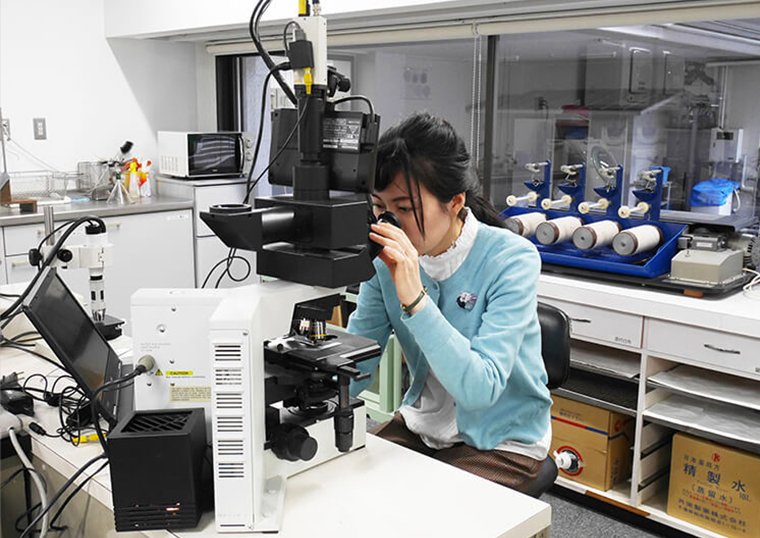

Quality Control (QC)

Sanyo has established its own standards and operating standards to provide safe and reliable supplies to both the planet and humanity.

We believe that giving consideration to the environment is linked to manufacturing that customers can love for a long time by focusing on technology and quality in a single clothing.

Sanyo has established its own Quality Control Standards. Staff from the Quality Control (QC) specialist group collaborate with related parties inside and outside the company to strictly control quality.

In addition, training sessions on quality and laws and regulations are held for brand-related people and all employees according to their content, in order to share a common awareness of quality.

By creating and supplying high-quality products that are safe, secure, and long-lasting for both the earth and human beings, we will lead to a better future.

Building and Maintaining Mutual Trust with Plants

Sanyo has established its own "Plant Management and Operation Standards" to ensure that the technical and quality-control items are being implemented at the plants.

In particular, we strictly check items related to needle management, equipment management, and meter reading procedures related to safety and security.

Regular QC Meetings are held at major plants to check the degree of achievement of quality targets, to prevent defective products, and to confirm whether the manufacturing system for safe and secure products is functioning.